- HOME

- Quality Control

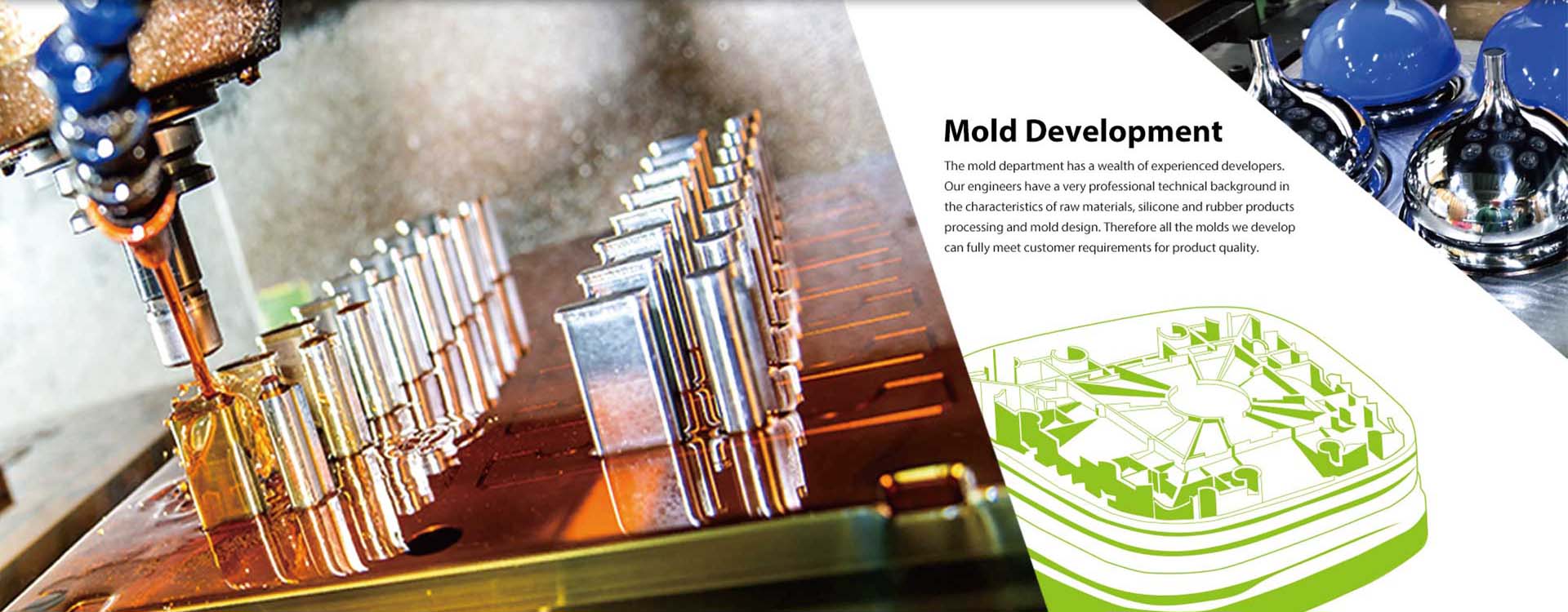

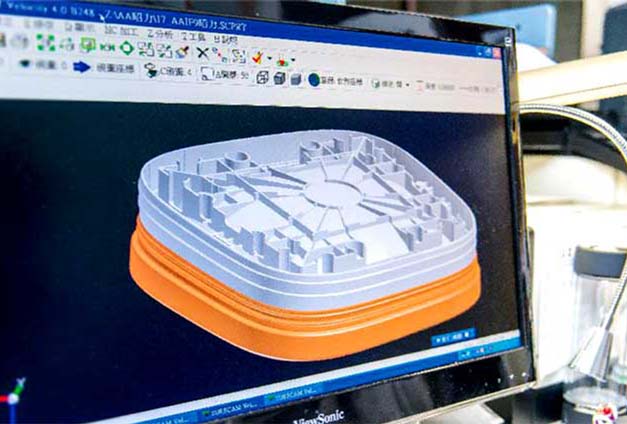

- Mold Development

Mold Processing

The mold department is fully equipped with a series of precision equipment. This equipment, combined with well-trained operators produce high precision molds. The integrated mold making proces development, processing, assembling, mold testing, and so dramatically shorten mold making time and product delivery

1.Inquiry period :

- Customers send inquiry detail (2D, 3D, photos, samples)

- JHAO YANG RUBBER provides technical checking and suggestion

- JHAO YANG RUBBER provides quotation

2.Order confirm:

- Order confirmation

- Mold design layout preparation

- Mold design layout approval

3.Mold making:

- Steel ordering

- Mold making

- Mold assembly

4.Mold trial:

- Mold trial with test1 samples delivery

- Sample dimension checking

- Sample approval

5.Molding products:

- upon request, we accept pilot run, low volume and mass production job.

- product delivery

6.Mold delivery:

- shipping documents preparation

- wooden case fumigation proceeded

- mold packing with standard export packed

- mold delivery & report to customer

Mold Storage

We have a specialized mold storage warehouse. All molds are controlled by a modern management system. We also conduct periodic maintenance to ensure mold quality and performance.